About Us

RVRN

RVRN

OUR STORY

In 2018, a small team of engineers had a vision. Automotive enthusiasts with engineers' eyes for skillful design, they had grown disillusioned with the poor construction and selection of aftermarket wheels. What if, they wondered, they could not only offer quality aftermarket wheels to car enthusiasts, but involve them in the process of designing the wheels as well? What if they could help them create their idea of the perfect wheel? This was the birth of RVRN Custom Forged Wheels.

OUR SERVICE

We believe that a wheel’s function does not have to compromise its form, and reflect this in all of our designs. Whether you have an SUV, sports car or otherwise exotic vehicle, our team can help you find the perfect fit for your ride from our collection, or help you bring your idea to life through our Custom Service. Every wheel we create represents the finest in aftermarket performance and luxury wheels, and is made to unlock your cars performance potential, maximize its handling, and have you driving the streets in style with your aftermarket rims.

OUR GOAL

The process starts from the ground up. It begins in the shop, and doesn’t end until the rubber hits the pavement. Our goal is to incorporate our passion for creation, innovation, craftsmanship and all things automotive into every wheel we make. However, our ambitions don’t stop there. We’re determined to become leaders in the wheel industry, and to offer the highest quality wheels and best service to our customers.

&

&

OUR APPROACH

CAD Modeling

We use parametric CAD software to design our wheels, allowing precision modelling to be within 0.01mm, and for us to easily assess and modify features against the design intent and the predicted outcome throughout the process. Every design will pass through multiple drafts until the look is perfect.

Design Optimization

When the core design is finalized, our designer begins enhancing the performance and look. Each set of wheels is designed with specific weight reduction strategies in mind, such as spoke hollowing and weight reduction pocketing. Concavity or dish depth is optimized as per client's request. Brake clearance will also be verified to make sure mounting the wheels will be hassle-free.

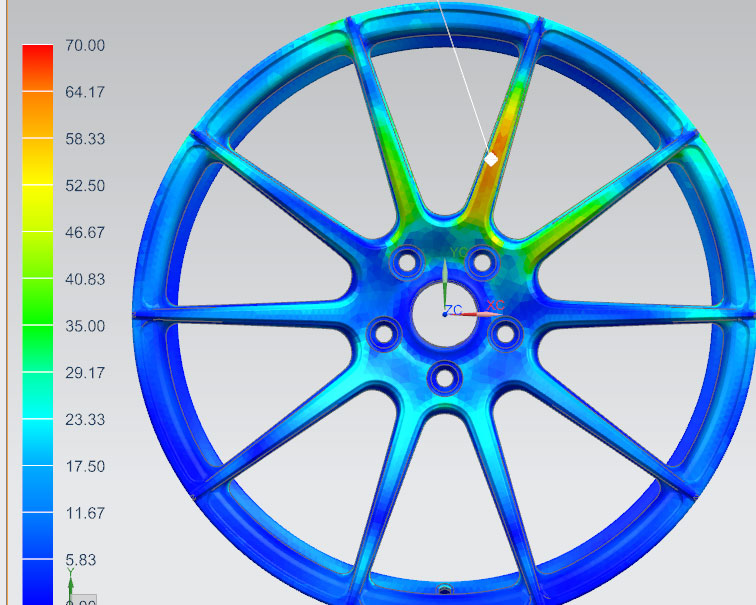

Finite Element Analysis

Before going into production, the designer will perform computer simulation tests - Finite Element Analysis - to make sure all applicable JLW, VIA and TUV safety standards are met. The highly predictable mechanical properties of forged 6061-T6 aluminum alloy allow us to pinpoint potential stress points in the wheel and predict its performance with FEA to an exceptional degree of accuracy.

ART OF PRECISION ENGINEERING

LIGHTWEIGHT CONSTRUCTION

PERFORMANCE PHYSICS

UNCOMPROMISED STYLING

%

%